Stress Differentials: By protecting different stress levels in adjoining spaces, airlocks make sure the stream of air is directed to stop contamination from transferring into cleaner spots.

So crucial monitoring of air tension routine maintenance is needed in all areas due to the fact any fall or rise in the force of any spot may possibly result in cross-contamination.

Anytime There exists a modify in air classification, a gowning action also happens. Staff are classified as the dirtiest entity moving into a cleanroom. Contaminants created by staff should be effectively encapsulated to limit particulate counts for the degrees appropriate for the cleanliness level in concern.

It’s not proposed as being the brine’s composition may possibly modify with Each and every batch. Begin clean for optimal success.

Managed environments with medium cleanliness specifications: Cascade airlocks are well-fitted to environments in which contamination Manage is important but will not require Serious containment or ultra-substantial cleanliness.

Some may perhaps perceive working with an airlock as intricate, but in reality, it’s a simple and powerful Resource that enhances the fermentation method.

Further Requirements: Now that The variability and amounts of fabric are acknowledged to maneuver thru the airlocks. Big consideration has to be compensated on this kind of functions, Cleaning and disinfection things to do, how this sort of pursuits are taken care of And the way the components are tracked with great deal numbers. Interest needs to be compensated to get more info the actual activity occurring while in the airlock.

In almost all of the pharmaceutical industries, a standard airlock system is used for the entry of Guys and supplies it truly is Incorrect follow.

Airlocks is often categorized into “cascading,” “bubble,” “sink” and “twin compartment” types; Just about every kind exhibits different airflow directions and strain dissimilarities in between the controlled environment, airlock, and corridor.

Staff airlocks, also referred to as gowning airlocks, are created to Handle the movement of staff entering or exiting cleanroom environments. These airlocks normally consist of two or more interlocking doorways divided by a small vestibule.

-Both doorways of airlock shouldn't be opened simultaneously. To start with open up a person doorway and enter into airlock from Class D then near that door and open up other door to enter into Class C.

one. Cleanliness Classifications: The airlock needs to be made in accordance with the cleanliness amounts of the adjacent rooms.

-monitoring of air force is necessary in all locations simply because any fall or increase in the pressure of any place could bring about cross-contamination.

airlock Areas are typically developed to maintain specific force associations with respect to managed environments and corridors. Even so, each time a doorway is remaining opened, the space’s air leakage in the doorway’s opening quickly turns into much better as more info opposed to leakage through minor cracks when doorways are shut.

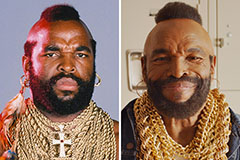

Mr. T Then & Now!

Mr. T Then & Now! Scott Baio Then & Now!

Scott Baio Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!